School Projects

University Of Pennsylvania Class Projects - BSE Class of 2020University of Florida - School of Architecture, CLICK HERE

GAMMA STERLING ENGINE - Machine Design and Manufacturing (MEAM 201 )

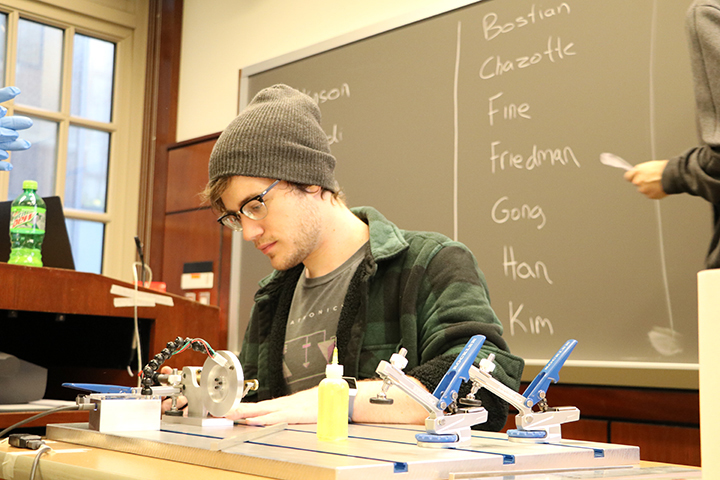

Meam Design 201 was a course focused on Machine Design and Manufacturing, I was tasked with designing half of the components for a Gamma Type Stirling Engine based on provided engineering drawings. My responsibilities included creating complete engineering drawings for the connecting rods, base, crank, and flywheel, while ensuring appropriate tolerances as per GD&T stack-up calculations for each individual part.

Over the course of the semester, I had access to a range of industrial machines that allowed me to bring my designs to life. I utilized both manual and numerically controlled milling machines and lathes to machine all the parts for the Stirling engine.

The Stirling engine itself features a piston and a displace that work together to move air between the heat sink and applied heat source located at the end of the stainless steel end cap. Throughout my machining process, I learned how to use various industrial machines, starting with a Manual/CNC Mill that had a digital readout. I also gained experience using a manual mill that also utilized a digital readout.

This project features a Stirling engine that I designed and fabricated during a machine shop course. Through this project, I gained hands-on experience with manual milling machines, manual lathes, and CNC-equipped manual mills. These machines allowed me to create precise components for the Stirling engine, which converts heat energy into mechanical work through cyclic compression and expansion of air or other working fluids.

I applied my knowledge of engineering drawings, material selection, and machining techniques to bring the Stirling engine to life. This project enhanced my skills in dimensional accuracy, tolerances, and surface finishes, ensuring the engine's optimal functionality. It was a valuable opportunity to bridge theoretical concepts with practical application, developing my problem-solving abilities and deepening my appreciation for the intricacies of machine design and fabrication.

Attached Picture Description: The picture showcases the fully assembled Stirling engine, highlighting its intricate components and the precision involved in its construction.

DESIGN OF MECHATRONIC SYSTEMS Battle Bots - MEAM 510 (Graduate Class )

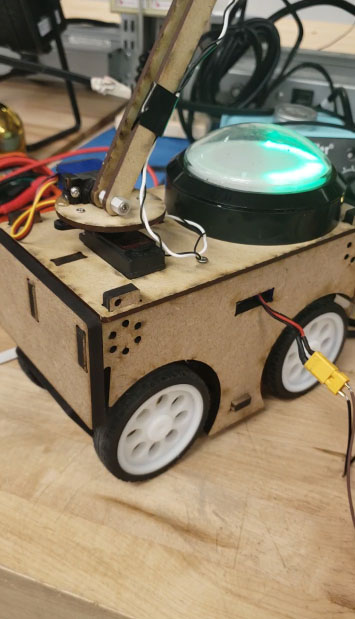

Description: This project involved designing and constructing a Battle Bot as part of a class assignment. In teams of three, we were tasked with creating a remote-controlled bot capable of engaging in a simulated battle. The bot consisted of several components, including a large pressable button with built-in LEDs, a rotatable swinging hammer arm, customizable body made of MDF panels, and even the controllers used to operate the bot.

The project encompassed various aspects of engineering and fabrication. We started by designing the bot's body using CAD software, precisely modeling the components and determining their placement. We then laser-cut the MDF panels that would comprise the structure. Additionally, we developed the circuits and electronics required to power the button, control the swinging arm and motors, and establish communication between the remote controller and the bot.

We also designed the controllers themselves. Using Arduino boards, we integrated joystick potentiometers and other components, allowing us to send network packets, using UDP protocols, to control the bot's movements and actions. This added another layer of complexity to the project, as we had to ensure seamless communication between the controllers and the bot's Arduino system.

Taking ownership of every stage, from CAD design to circuitry, programming, and controller development, we gained a comprehensive understanding of the entire process. This project showcased our problem-solving abilities, teamwork, creativity, and technical skills in engineering, fabrication, and electronics.

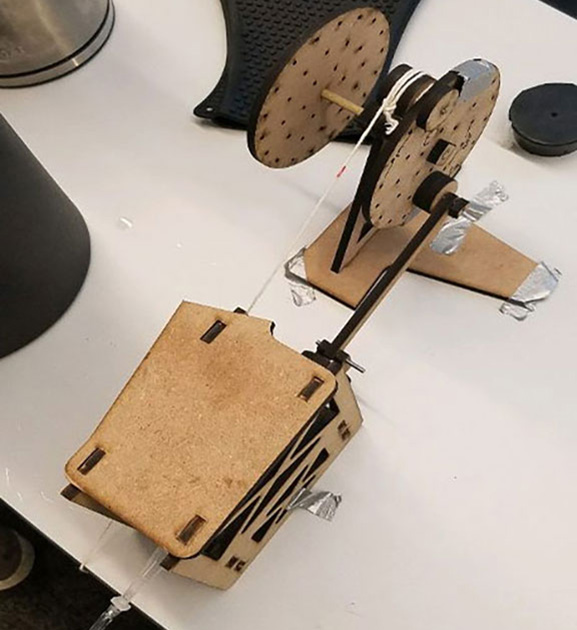

Attached Picture Description: The picture showcases our Battle Bot, displaying the unique design of the body, the button with LEDs, and the swinging hammer arm.

MEAM DESIGN LAB Piston-based Rectilinear-to-Rotational Converter

Description: This project involved the design and implementation of a piston-based rectilinear-to-rotational converter. In this assignment, we developed a system that utilized the expansion of water due to heating to drive a piston, which, in turn, rotated a wheel to perform a specific mechanical function, such as lifting an object.

Through meticulous planning and engineering, we created a mechanism that harnessed the power of thermal expansion to convert linear motion into rotational motion. By carefully selecting materials, designing the piston assembly, and optimizing the transfer of heat energy, we achieved an efficient and reliable conversion process.

This undertaking provided valuable experience in conceptualizing and implementing innovative solutions. It showcased our ability to leverage principles of thermodynamics, mechanics, and engineering design to create functional and practical devices. This project not only demonstrated our technical skills and problem-solving capabilities but also emphasized our ability to adapt and apply engineering principles in real-world scenarios.

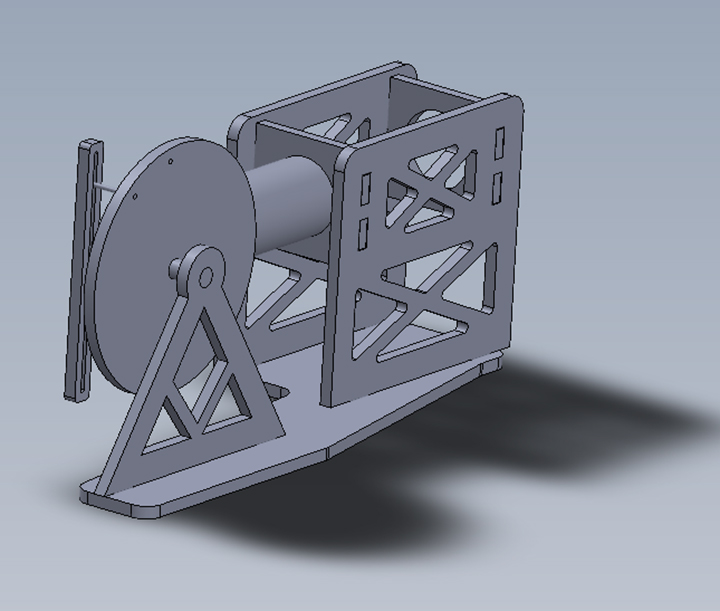

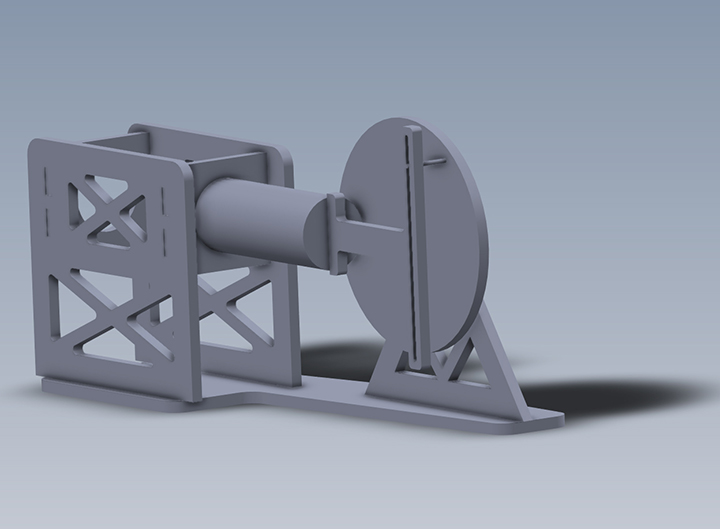

Below: Earlier designs of the converter, which were then improved upon after testing.

Another view of the design done earlier of the converter, which were then improved upon after testing.

VAWT Vertical Axis Wind Turbine MEAM 347

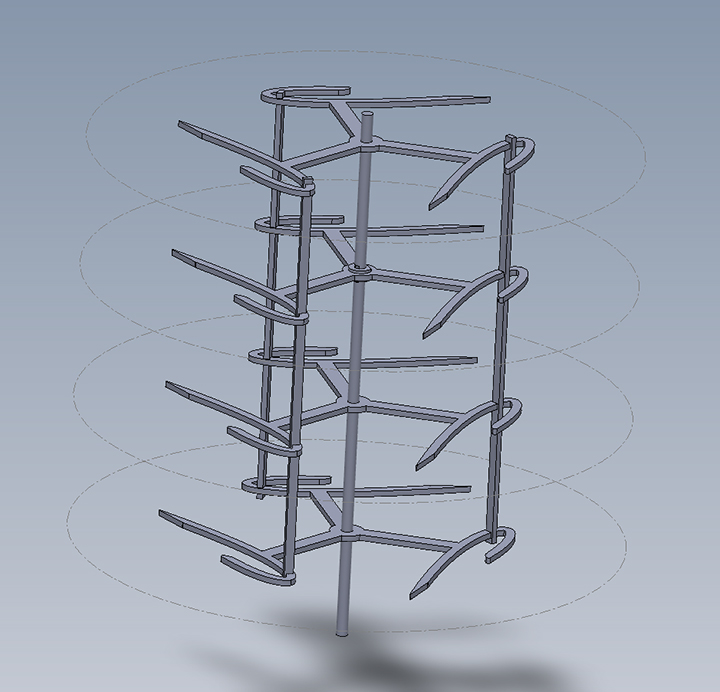

Description: This project focused on designing and constructing a vertical wind turbine with the goal of generating the highest electrical power output. The turbine was attached to a moving cart to simulate wind conditions. Our design consisted of a three-vane vertical wind turbine, featuring a four-level skeleton made of MDF tri-arms arranged around a single axis. To create the vanes, we attached paper to the skeleton, ensuring efficient wind capture and rotation.

Through careful consideration of aerodynamic principles and turbine design, we aimed to optimize the conversion of wind energy into electrical power. Our approach involved experimenting with different vane shapes, sizes, and orientations to maximize performance. We also incorporated an electrical generator to capture and measure the electrical power generated by the turbine.

This project allowed us to explore the intricacies of wind turbine design, including the interplay between aerodynamics, structural integrity, and electrical generation. By analyzing the data collected during the experiments, we gained insights into the performance factors of the turbine, such as wind speed, vane design, and power output.

The vertical wind turbine project highlighted our ability to apply engineering principles, adapt to varying conditions, and utilize creative problem-solving to optimize energy conversion. It exemplified our commitment to sustainable solutions and our enthusiasm for harnessing renewable energy sources.

Attached Picture Description: The picture showcases our vertical wind turbine with three vanes made of paper attached to the MDF skeleton. It illustrates the design of the turbine and provides a visual representation of our innovative approach to capturing wind energy.

CAPSTONE Senior Design Project: Deployable Airbag for Pole Vaulters

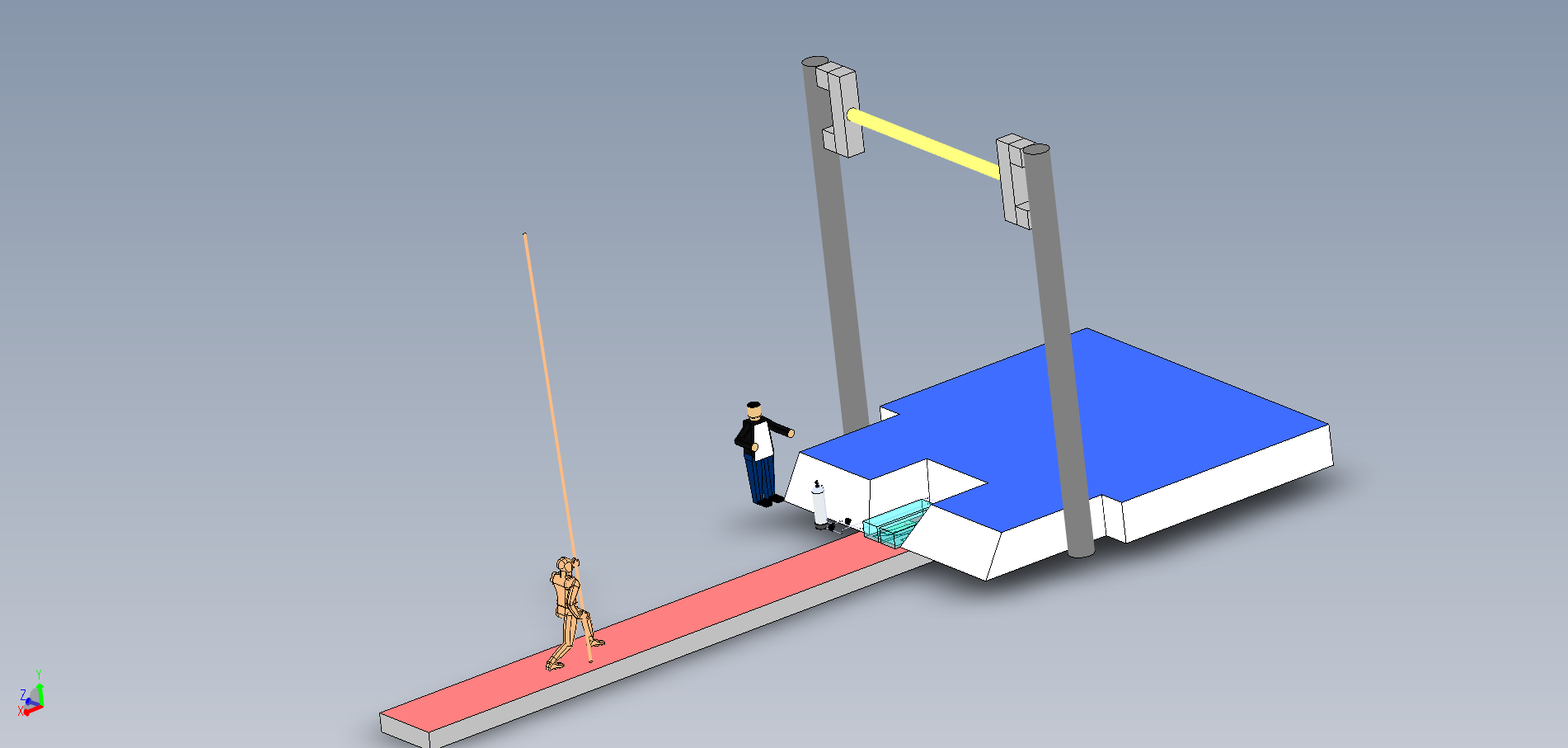

Description: For our senior design project, we developed a deployable airbag system aimed at providing a semi-cushioned landing for pole vaulters in case they failed to clear the jump. The project focused on ensuring the safety and well-being of athletes during the pole vaulting event, particularly in relation to the plant box—a designated area where the pole vaulter plants their pole to generate momentum for the jump.

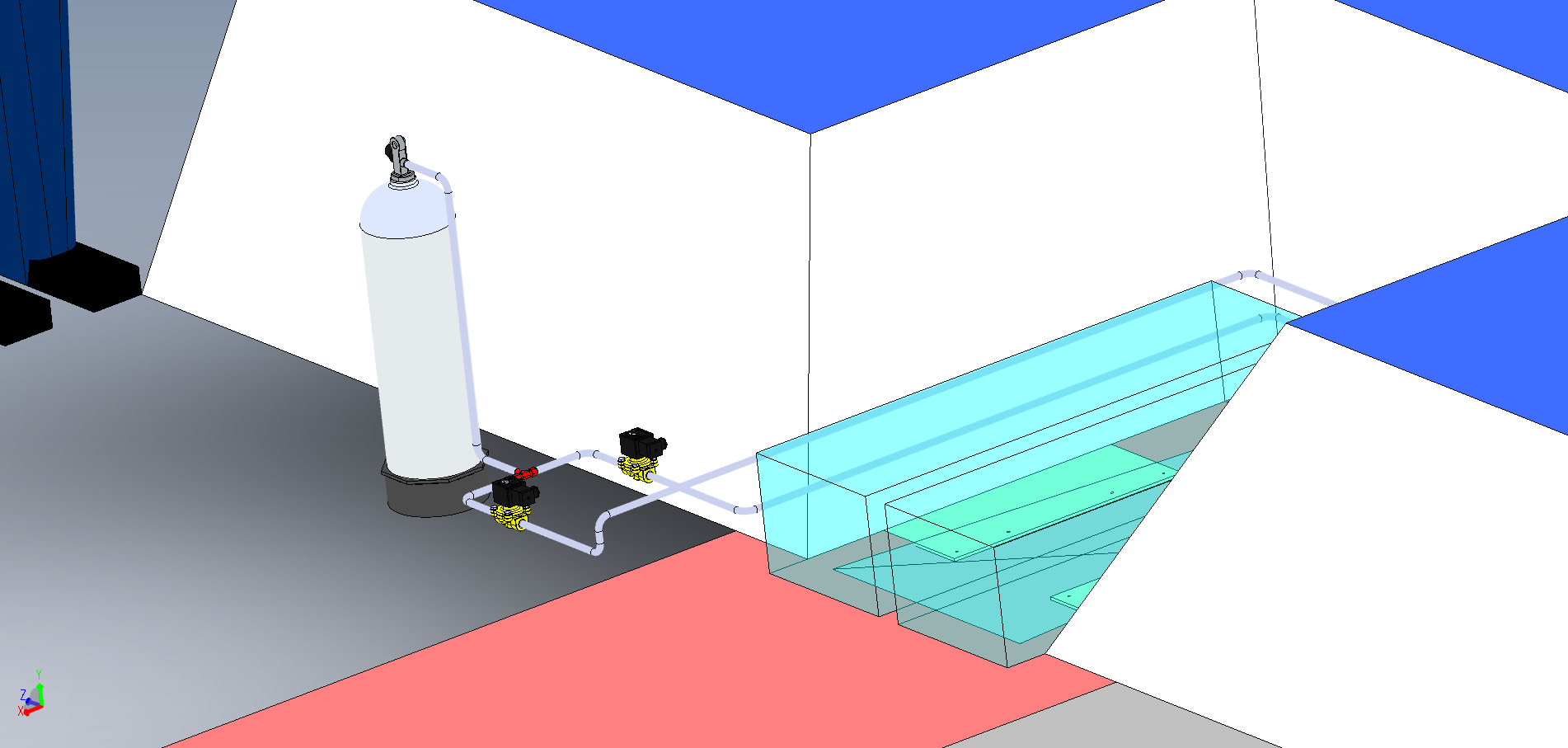

The plant box is designed to provide a sturdy and stable foundation for the pole vaulter during takeoff. However, in the event of a failed jump, a safe landing becomes crucial to minimize the risk of injury. The attached CAD designs showcase the comprehensive system, including the pole vault starting/landing area, the deployed airbag, the connected piping and compressed air tank, and the quick-release valves controlled remotely by a safety official.

Our team recognized the importance of a responsive and cushioned landing to mitigate potential injuries. The deployable airbag system was meticulously designed to deploy quickly to soften the impact during a failed jump, minimizing the risk to the pole vaulter. By integrating advanced materials, precise control mechanisms, and a pneumatic system, we ensured a swift and effective deployment of the airbag upon impact.

The CAD designs depict the thoughtful integration of the airbag system into the pole vaulting environment, highlighting its proximity to the plant box. This placement ensures that, in the event of a failed jump, the airbag provides an additional layer of safety and cushioning to protect the athlete during their descent. Our senior design project exemplifies our commitment to safety and showcases our ability to apply engineering principles in innovative ways.

Attached Picture Description: The pictures showcase the CAD designs of our deployable airbag system for pole vaulters. They depict the pole vault starting/landing area, the deployed airbag, the interconnected piping, the compressed air tank, and the quick-release valves controlled remotely. The CAD designs emphasize the integration of the airbag system in close proximity to the plant box, ensuring a swift and cushioned landing to minimize the risk of injury during a failed jump.

nbsp;

nbsp;

Other Projects

Pen and Ink Drawing

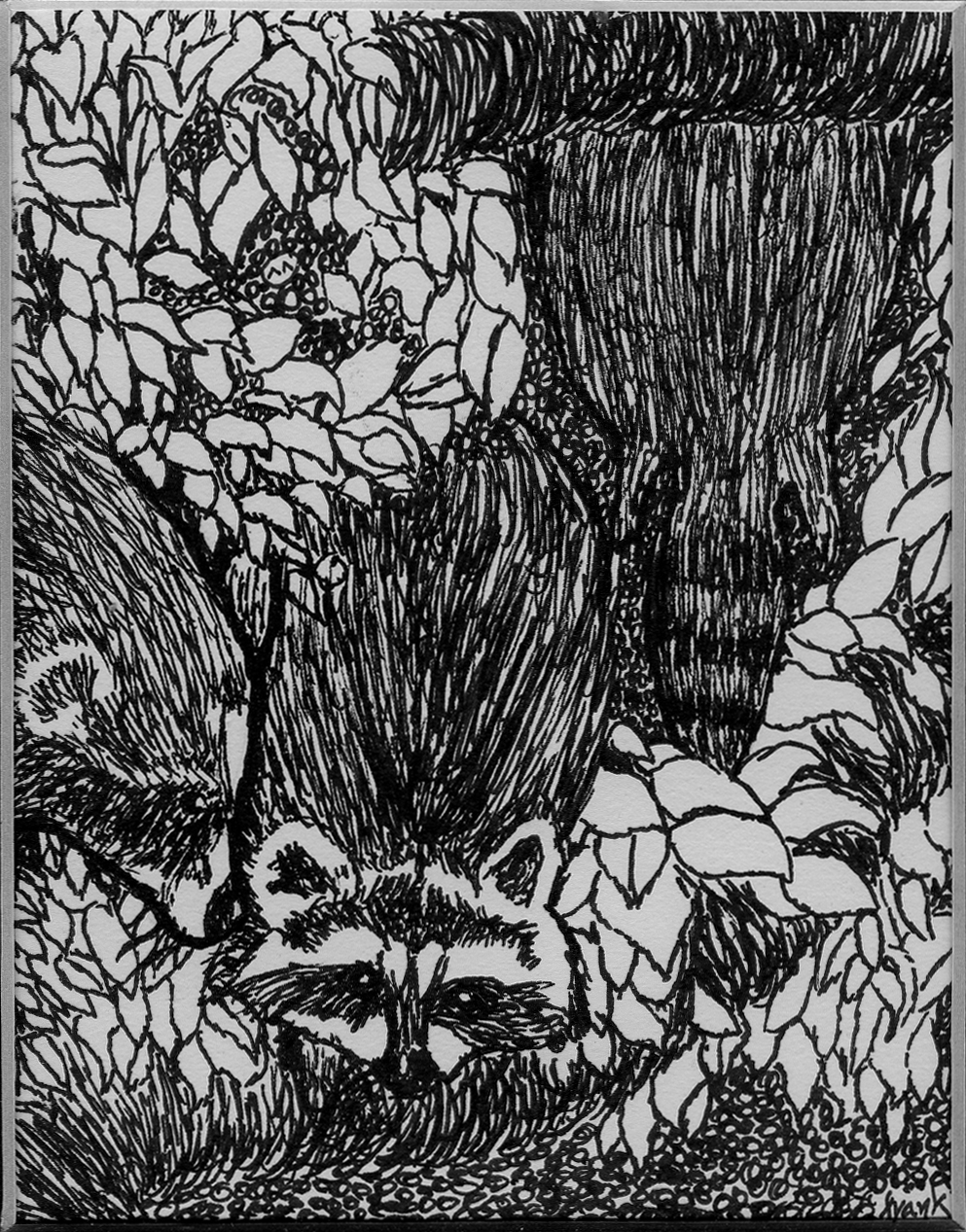

Project: Raccoon Artwork

Description: As part of my portfolio, I have included a piece of artwork that I created during my high school years. This artwork showcases my ability to sketch and demonstrates my artistic capabilities, which can be advantageous in various creative endeavors. The drawing depicts three raccoons in a natural setting, with two of them drinking water from a pond while one hangs from a nearby branch. The artwork is a pen drawing based on a reference photo, serving as a small example of my ability to translate a client's vision into a visual representation.

By including this artwork in my portfolio, I aim to highlight my versatility as an engineer with creative skills. While my primary focus is on mechanical engineering and problem-solving, I also possess a passion for artistic expression. This drawing exemplifies my attention to detail, observational skills, and the ability to bring ideas to life through visual mediums.

Artistic ability can be valuable in engineering projects that require visual communication, such as concept development, technical illustrations, or collaborating with clients to bring their ideas to fruition. It showcases my capacity to understand and translate a client's vision into a tangible representation, bridging the gap between imagination and reality.

Attached Picture Description: The picture depicts my pen drawing of three raccoons in a natural setting, drawn from a reference photo. Two raccoons are depicted drinking water from a pond, while a third raccoon hangs from a nearby branch.

Graduation from SAAST, University of Pennsylvania 2012

Summer Program: Engineering Summer Academy at Penn (ESAP) - SAAST

Description: I had the privilege of being accepted into the prestigious summer program called the Engineering Summer Academy at Penn (ESAP) - Summer Academy in Applied Science and Technology (SAAST) at the University of Pennsylvania. This highly competitive program welcomed only 35 students from across the country to explore the field of Engineering and Robotics at the college level while still in high school.

ESAP's SAAST program offered an intensive and immersive three-week experience that combined advanced theoretical knowledge with hands-on practical applications in cutting-edge technologies. It was designed to provide exceptional math and science students, like myself, with the opportunity to delve into the fascinating world of Engineering before college.

Situated on the historic campus of the University of Pennsylvania, right in the heart of Philadelphia, the program provided not only exceptional academic resources but also access to a wide array of activities and opportunities available within the Penn community. This unique environment allowed me to fully engage in the program and make the most of my time exploring Engineering and Robotics.

Being part of the ESAP's SAAST program was a transformative experience that further solidified my passion for Engineering and Robotics. It provided me with invaluable exposure to advanced concepts, state-of-the-art technologies, and the opportunity to collaborate with like-minded students from diverse backgrounds. This immersive program empowered me to expand my knowledge, refine my skills, and make lasting connections within the field.

I was one of only 35 students across the country accepted into the prestegious summer SAAST program at the University of Pennsylvania - Engineering and Robotics Study while in high school.

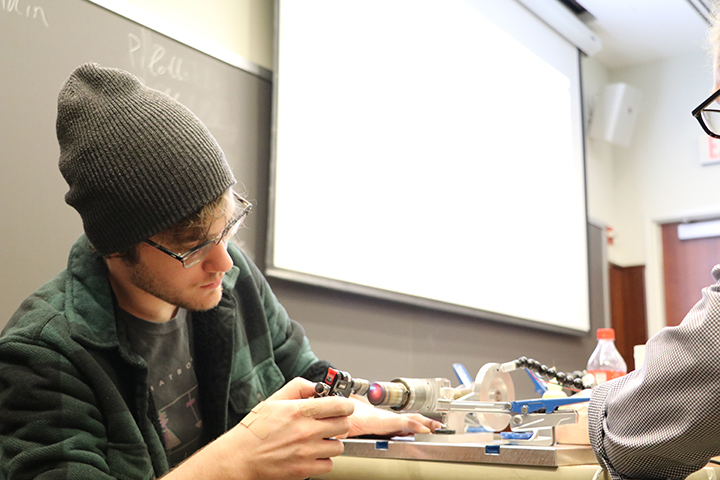

This is what happens when you love what you do! All night labs!

Finally, Graduation from University of Pennsylvania, Class of 2020, Mechanical Engineering & Applied Mechanics, BSE