Work Projects

Skills used: Several programming languages and tools: using SolidWORKS, MatLab, Python, Unity, C+,C++,C# with some Magento, HTML, MySql experience

PEGEEN.COM Orlando FL Engineering Lead, Developer and Chief Technology Specialist

During my time at Pegeen, I played a vital role in spearheading transformative projects and revitalizing the company's online presence. One of my significant accomplishments was completely rewriting Pegeen's ecommerce site, which had undergone multiple iterations since its launch in 1995 but required a substantial upgrade. This involved extending the functionality from design to sales, allowing customers to purchase the unique combinations they designed using the Dress Dreamer, a virtual dress builder I created in Unity. This concept was groundbreaking in the children's wear sector, where such a virtual closet was previously unheard of. Furthermore, I spearheaded the development of a VR store, which is set to launch in the third quarter of 2023. This immersive shopping experience will provide customers with a unique and interactive way to explore Pegeen's offerings.

Additionally, I collaborated closely with costume designers using SOLIDWORKS to engineer and design large-scale costumes for theatre, ballets, and stage productions. This required creating supported frames and ensuring the costumes met the specific requirements of each production.

In my role, I took on various business matters, including setting up the company with essential applications and programs to handle growth and implementing remote solutions. I also worked closely with the CEO to prepare loan applications for Covid Relief, including a comprehensive 11-tabbed spreadsheet covering marketing, past sales, projects, COGs, and more, which garnered commendation from the SBA Director. Additionally, I implemented a robust BOM system and established a streamlined process to track overseas purchases, including addressing transportation issues from suppliers.

My contributions at Pegeen encompassed a wide range of responsibilities, from technical expertise in software development and 3D design to strategic business initiatives. These projects demonstrate my ability to drive innovation, create immersive experiences, and effectively collaborate with cross-functional teams to achieve organizational objectives.

Projects included:

Using SOLIDWORKS, working with the costume designers to design and engineer to create large scale costumes requiring supported frames for the theatre, ballets and stage productions;

Oversight and development of new site which was a grounds-up reconfiguration, design and related backlink issues which were imperative as so much of company's presence comes from 130k backlinks from Pinterest; Google; and more;

Reimagined a way for customers to design their garments by creating a custom dress builder called "Pegeen Dress Dreamer" in Unity;

VR Store (completing) which will launch in 3rd quarter 2023;

Adapting the Dress Dreamer to be used in their retail stores as a "magic mirror" and built prototype;

Oversaw business matters such as setting company up with various applications and programs to handle growth, setting up remote solutions;

Worked with CEO to prepare loan applications for Covid Relief including a 11-tabbed spreadsheet that covered marketing, past sales, projects, COG, and more which garnered a compliment from the SBA Director;

Created BOM system and created a way to track purchases from overseas including transportation issues from suppliers

Ongoing project - A VR Store is being created using Unity. Porting Dress Dreamer and modifying so customers not able to visit store can visit using their VR headpieces. It is hoped the concept will convince Disney to allow them to open stores at Disney locations world-wide.

Ongoing project 2 -A magic mirror system is being installed that will allow customers to be able to use the program I built to "see" what it looks like when they "try it on" in their store.

Project: Stage Costume Design and Engineering, SolidWORKS

Description: As part of my role in a children's and costume company, I worked on multiple stage costume designs, one of which involved creating a unique costume that presented specific challenges due to proprietary concerns. Unfortunately, due to NDA restrictions, I am unable to showcase the underframe, which is a crucial component of the costume design. However, I can provide insights into the overall project and my contributions to its success.

The costume was designed to accommodate multiple children underneath, incorporate a platform to move the actor across the stage, and seamlessly fit through side curtains. It required a robust framework and a specialized harness to support the structure while ensuring the safety and comfort of the actor. The costume's innovative features and functionalities were instrumental in creating a captivating and dynamic stage presence.

To tackle the complex engineering aspects of the project, I utilized SolidWORKS, a powerful CAD software, to design the pattern for the craftsmen responsible for cutting and assembling the framework of the costume. This meticulous process ensured precise alignment and fit of the costume over the framework, resulting in a visually stunning and functional stage costume.

Throughout the project, I collaborated closely with craftsmen, costume designers, and other stakeholders to ensure the seamless integration of the design, engineering, and artistic elements. The interdisciplinary nature of this endeavor demanded effective communication and coordination to bring the vision to life.

Overall, this project was one of several stage costumes I was entrusted with creating. It exemplified my ability to combine engineering principles, artistic vision, and problem-solving skills to deliver exceptional results in the realm of costume design and engineering. Here you see the costume after the craftspeople sewed the costume for first fitting over the framework.

This was one of multiple stage costumes (6) or designs that I was tasked with creating.

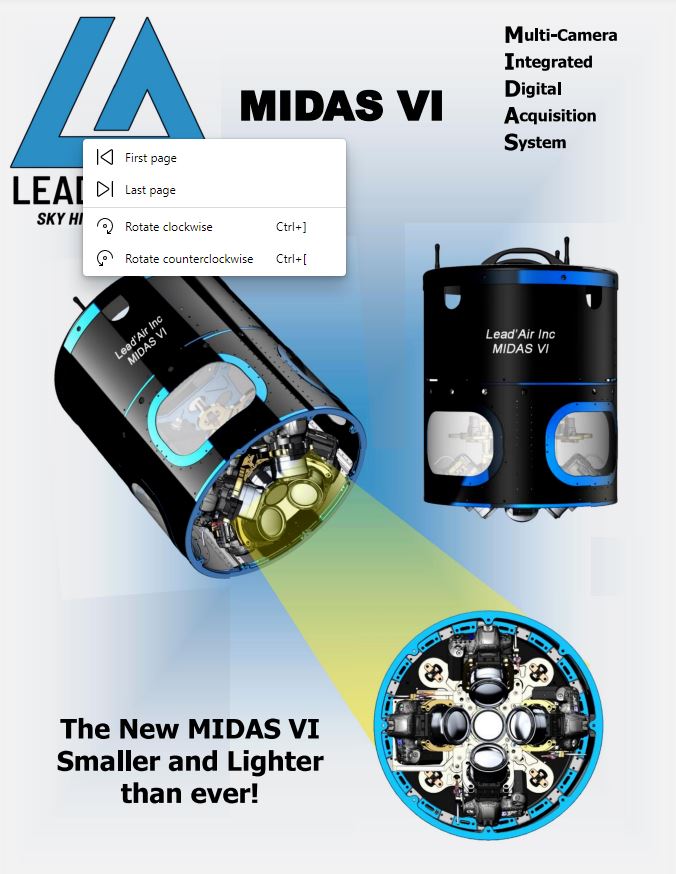

Lead Air/Hard Ware Internship, Year 2

At Lead'Air, I played a pivotal role in various aspects of the product life cycle, utilizing my expertise in CAD modeling and engineering to drive successful outcomes. I employed SOLIDWORKS to engineer and create accurate CAD models, ensuring the integrity and quality of the design. Additionally, I maintained the existing CAD database, reviewing compliance of machined parts and providing valuable input to enhance their functionality.

Throughout the product life cycle, I contributed to multiple stages, including sourcing and pricing hardware, engaging in rapid prototyping, collaborating with machinists to refine proper fit, and ensuring the proper assembly of components. I also took charge of packaging finished products, paying meticulous attention to detail to ensure safe transportation and delivery to customers. Moreover, I provided software update recommendations to the company, performing cost analysis to identify outdated software systems that needed modernization. I then produced a comprehensive Standard Operating Procedure (SOP) manual, enabling existing employees to seamlessly transition their skill sets to the new software edition.

Ensuring compliance with safety requirements was a key priority in my role. I worked diligently to adhere to the guidelines set by the FAA and other regulatory boards, ensuring that all parts were produced safely and met the necessary safety standards. Additionally, I reviewed CAD models using SOLIDWORKS, meticulously analyzing and correcting engineering drawings to guarantee precision and accuracy. I also conducted thorough testing and refinement of machined parts to ensure optimal performance and functionality.

My contributions at Lead'Air underscore my ability to work across various stages of the product life cycle, employing CAD expertise, attention to detail, and adherence to safety regulations to deliver high-quality and reliable products.